All About Reed Maintenance

Prompt and On Time Delivery

Most important factor for service provider is quick completion of work and on time material delivery, and we gain our user’s great trust for our prompt services. All work processes and order management are done in committed time.

Reed Maintenance

For a guaranteed higher efficiency in loom shed, it is mandatory to inspect and maintain old reeds on regular basis. This helps increasing reed life and fabric quality, we suggest inspection of reeds for;Air Flow Checking System

In weaving department reed maintenance is an important process. With time and constant usage during weaving process, the air flow of profile reeds gets changed. This directly affects weft carrying capacity throughout the width of nozzle. Fabric construction and yarn type also generates grooves in the reeds. So, we recommend air flow checking and re-calibration after certain uses of reeds. This has following advantages;

In weaving department reed maintenance is an important process. With time and constant usage during weaving process, the air flow of profile reeds gets changed. This directly affects weft carrying capacity throughout the width of nozzle. Fabric construction and yarn type also generates grooves in the reeds. So, we recommend air flow checking and re-calibration after certain uses of reeds. This has following advantages;

Removal of Grooves generated in Tunnel of Air Jet Reeds

We have developed techniques through experience of many reeds, to determine the condition of reeds for re-conditioning through polishing. And proper polishing to ensure least effect on air consumption pattern of reed. Also to do polishing without disturbing physical structure of reeds.

We have developed techniques through experience of many reeds, to determine the condition of reeds for re-conditioning through polishing. And proper polishing to ensure least effect on air consumption pattern of reed. Also to do polishing without disturbing physical structure of reeds.

Reed Polishing & Cleaning

Polishing & Cleaning both are very important aspect of reed maintenance. After running of reeds on any machine for pro-longed period it is seen that fluff & size chemicals have formed a layer between dents, which may increase the air resistance in a weft guide path of profile reed andinterrupt the efficiency of loom. To avoid such issues Reed polishing &Cleaning is advisable. After serial of trials of someneutral cleaning agent and gentle polishing techniques developed by us, it is observed that reeds are always cleaned to the satisfaction level of our esteemed customers. And they have appreciated our efforts after finding improvements in the performance of reeds on looms. Because of our rich experience of handling reeds we know How to clean, Where to clean, Where to be gentle and where to be tough.

Polishing & Cleaning both are very important aspect of reed maintenance. After running of reeds on any machine for pro-longed period it is seen that fluff & size chemicals have formed a layer between dents, which may increase the air resistance in a weft guide path of profile reed andinterrupt the efficiency of loom. To avoid such issues Reed polishing &Cleaning is advisable. After serial of trials of someneutral cleaning agent and gentle polishing techniques developed by us, it is observed that reeds are always cleaned to the satisfaction level of our esteemed customers. And they have appreciated our efforts after finding improvements in the performance of reeds on looms. Because of our rich experience of handling reeds we know How to clean, Where to clean, Where to be gentle and where to be tough.

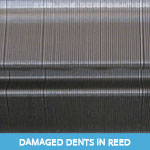

Replacement and Realignment work

Sometimes by mistake of handling reeds, or improper storage conditions the reed profile gets bent or the air flow gets disturbed in certain portion of reed. Also, certain accidents yielding minor or major dent damage makes the reed unusable. We ensure trouble free working of those reeds after re-conditioning by replacing or removing the damaged portion with O.K. Dents. With this facility user can take the same reed for re-use without the damaged portion.

Sometimes by mistake of handling reeds, or improper storage conditions the reed profile gets bent or the air flow gets disturbed in certain portion of reed. Also, certain accidents yielding minor or major dent damage makes the reed unusable. We ensure trouble free working of those reeds after re-conditioning by replacing or removing the damaged portion with O.K. Dents. With this facility user can take the same reed for re-use without the damaged portion.

Extra Binding / Double Binding of Old Reeds

Certain construction of fabric demands more stability of reeds during weaving operation. When customer feels requirement of additional binding to enhance dent stability we serve additional binding on top and/or on bottom channel. Certain users feels they prevent machine vibration effecting on reeds by this action. Here we ensure precision of work with absolutely safe, straight binding with zero effect on dent spacing.

Certain construction of fabric demands more stability of reeds during weaving operation. When customer feels requirement of additional binding to enhance dent stability we serve additional binding on top and/or on bottom channel. Certain users feels they prevent machine vibration effecting on reeds by this action. Here we ensure precision of work with absolutely safe, straight binding with zero effect on dent spacing.